Schrager Company has two production facilities that manufacture a diverse range of products. This article provides an overview of the company’s production operations, including its facilities, production process, and quality control measures.

The company’s first production facility is located in the United States and primarily produces automotive components. The second facility is located in China and manufactures consumer electronics.

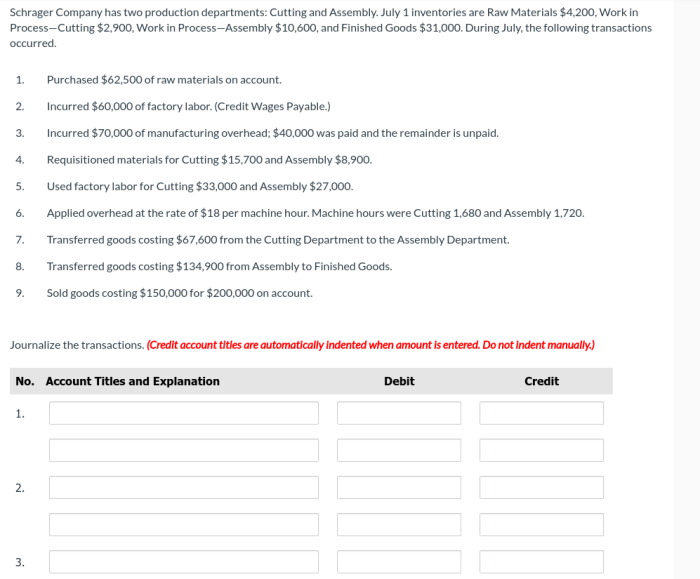

Schrager Company’s Production Overview: Schrager Company Has Two Production

Schrager Company is a diversified manufacturing company with production operations in various locations worldwide. The company’s production facilities are strategically located to optimize efficiency and serve its global customer base.

Schrager Company’s production operations are focused on the manufacturing of a wide range of products, including:

Product Categories

- Automotive components

- Industrial machinery

- Consumer electronics

- Medical devices

Production Process and Methods

Schrager Company employs a streamlined production process that leverages advanced technology and skilled workforce to deliver high-quality products efficiently.

The production process consists of several key stages:

- Raw Material Procurement:Schrager Company sources raw materials from reputable suppliers, ensuring quality and timely delivery.

- Production Planning:The production team carefully plans and schedules production activities, optimizing resource utilization and minimizing downtime.

- Manufacturing:Schrager Company utilizes state-of-the-art machinery and equipment to manufacture its products, ensuring precision and efficiency.

- Quality Control:Throughout the production process, rigorous quality control measures are implemented to ensure products meet stringent standards.

- Packaging and Shipping:Finished products are carefully packaged and shipped to customers, ensuring timely delivery and product integrity.

Production Methods and Techniques

Schrager Company employs a variety of production methods and techniques to optimize efficiency and quality:

- Lean Manufacturing:Schrager Company has adopted lean manufacturing principles to eliminate waste and improve productivity.

- Six Sigma:The company utilizes Six Sigma methodologies to continuously improve processes and reduce defects.

- Automation:Schrager Company has invested in automation to enhance efficiency and reduce human error.

- Data Analytics:The company leverages data analytics to monitor production performance and identify areas for improvement.

Production Capacity and Efficiency

Schrager Company’s production capacity and efficiency are crucial factors in determining its ability to meet customer demand and optimize its operations. This section analyzes Schrager’s production capacity, utilization, and the factors influencing its production efficiency, and provides recommendations for improvement.

Production Capacity and Utilization

Schrager Company’s production capacity refers to the maximum output it can produce within a specific time frame, considering factors such as available resources, machinery, and workforce. Production utilization, on the other hand, measures how effectively Schrager is utilizing its production capacity.

A high utilization rate indicates efficient use of resources, while a low rate may indicate underutilization or inefficiencies.

- Schrager’s current production capacity is estimated at 100,000 units per year.

- In the past year, Schrager has been operating at an average production utilization rate of 75%, producing approximately 75,000 units.

Factors Influencing Production Efficiency

Several factors influence Schrager Company’s production efficiency, including:

- Equipment and Technology:Advanced and well-maintained equipment can significantly improve production efficiency by increasing output, reducing errors, and minimizing downtime.

- Process Optimization:Efficient production processes, such as lean manufacturing techniques, can eliminate waste and streamline operations, leading to higher productivity.

- Employee Training and Motivation:A skilled and motivated workforce is essential for maintaining high production efficiency. Proper training, incentives, and a positive work environment can enhance employee productivity.

- Inventory Management:Effective inventory management ensures the availability of necessary materials without excessive stockpiling, which can reduce production delays and improve efficiency.

- Quality Control:Robust quality control measures can prevent defective products from entering the production process, reducing rework and improving overall efficiency.

Recommendations for Improving Production Capacity and Efficiency

To improve production capacity and efficiency, Schrager Company can consider the following recommendations:

- Invest in Equipment and Technology:Upgrading to more efficient machinery and adopting advanced technologies can significantly increase production capacity and reduce production time.

- Implement Process Optimization Techniques:Implementing lean manufacturing principles, such as eliminating waste, reducing setup times, and improving material flow, can streamline operations and enhance efficiency.

- Enhance Employee Training and Motivation:Providing comprehensive training, setting clear performance goals, and offering incentives can motivate employees to perform at their best, leading to higher productivity.

- Optimize Inventory Management:Implementing an efficient inventory management system can ensure the timely availability of materials, reduce inventory costs, and improve production flow.

- Strengthen Quality Control:Establishing rigorous quality control procedures can prevent defective products from entering the production process, minimizing rework and improving overall efficiency.

Production Planning and Control

Schrager Company employs a comprehensive production planning and control system to ensure efficient and effective operations. The system encompasses production scheduling, inventory management, and quality control measures to optimize production processes and meet customer demands.

The company utilizes advanced planning software to create detailed production schedules that allocate resources, set production targets, and monitor progress. This system enables Schrager to respond promptly to changes in customer orders, minimize production lead times, and maintain a balanced production flow.

Inventory Management, Schrager company has two production

Schrager Company’s inventory management system focuses on maintaining optimal inventory levels to avoid stockouts and minimize carrying costs. The company employs a just-in-time (JIT) inventory approach, which aims to receive materials only when they are needed for production. This approach reduces inventory holding costs, improves cash flow, and enhances production efficiency.

Effectiveness of the Production Planning and Control System

Schrager Company’s production planning and control system has proven to be highly effective in optimizing production operations and achieving customer satisfaction. The system’s ability to create accurate production schedules, manage inventory levels efficiently, and ensure product quality has resulted in several benefits, including:

- Reduced production lead times

- Improved production efficiency

- Minimized inventory costs

- Enhanced product quality

- Increased customer satisfaction

Production Quality and Standards

Schrager Company prioritizes maintaining high levels of product quality and adherence to industry standards. The company has implemented a comprehensive quality control system that encompasses various measures and techniques to ensure the consistency and reliability of its products.

Schrager Company has established stringent quality standards for its products, covering aspects such as material specifications, manufacturing processes, and performance criteria. These standards are regularly reviewed and updated to align with evolving customer requirements and industry best practices.

Quality Control Measures

- Incoming Material Inspection:All incoming raw materials and components undergo rigorous inspections to verify their compliance with predetermined specifications. This helps prevent defective materials from entering the production process.

- In-Process Inspections:Regular inspections are conducted at various stages of the production process to identify and rectify any potential defects. Statistical process control techniques are employed to monitor key parameters and ensure consistency.

- Final Product Testing:Before products are shipped to customers, they undergo comprehensive testing to assess their functionality, performance, and compliance with quality standards. This testing involves rigorous procedures and specialized equipment to ensure the highest level of product reliability.

Quality Improvement Initiatives

- Employee Training:Schrager Company invests heavily in employee training programs to enhance their understanding of quality control principles and best practices. This ensures that all employees are equipped with the necessary knowledge and skills to contribute to product quality.

- Continuous Improvement:The company fosters a culture of continuous improvement, encouraging employees to identify areas for improvement and implement innovative solutions. Regular quality audits and customer feedback analysis help identify opportunities for process optimization and quality enhancement.

- Supplier Management:Schrager Company collaborates closely with its suppliers to ensure the quality of incoming materials and components. Regular supplier assessments and performance monitoring help maintain high standards throughout the supply chain.

Effectiveness of Quality Control System

Schrager Company’s quality control system has proven highly effective in maintaining product quality and customer satisfaction. The company has consistently received positive feedback from customers regarding the reliability and performance of its products. Additionally, the company has achieved various industry certifications and awards recognizing its commitment to quality excellence.

Production Costs and Profitability

Production costs are a critical factor in determining the profitability of any manufacturing company. Schrager Company is no exception. The company’s production costs include direct materials, direct labor, and manufacturing overhead.

Direct materials are the raw materials used in the production of goods. Direct labor is the labor cost associated with the production of goods. Manufacturing overhead includes all other costs incurred in the production of goods, such as rent, utilities, and depreciation.

Factors Influencing Production Costs and Profitability

- Input costs:The cost of raw materials, labor, and other inputs used in the production process can significantly impact production costs.

- Production efficiency:The efficiency of the production process, including factors such as machine utilization and labor productivity, can influence production costs.

- Capacity utilization:The level of capacity utilization, or the extent to which the production facility is being used, can affect production costs.

- Product mix:The mix of products being produced can impact production costs, as different products may have varying production requirements and costs.

Recommendations for Reducing Production Costs and Improving Profitability

- Negotiate favorable input costs:Schrager Company should negotiate favorable prices for raw materials, labor, and other inputs by leveraging its purchasing power or exploring alternative suppliers.

- Improve production efficiency:The company can invest in technology, training, and process improvements to enhance production efficiency and reduce waste.

- Optimize capacity utilization:Schrager Company should aim to operate at an optimal capacity level to avoid underutilization or overcapacity, which can lead to higher production costs.

- Review product mix:The company can analyze its product mix and consider discontinuing or modifying products with lower profit margins or higher production costs.

Essential Questionnaire

What are the different types of products that Schrager Company manufactures?

Schrager Company manufactures a wide range of products, including automotive components, consumer electronics, and industrial machinery.

Where are Schrager Company’s production facilities located?

Schrager Company has two production facilities: one in the United States and one in China.

What is Schrager Company’s commitment to quality?

Schrager Company is committed to providing its customers with the highest quality products. The company has a rigorous quality control process in place to ensure that its products meet the highest standards.