Fixed ladders without cages or wells are a unique and specialized type of ladder, offering advantages and considerations distinct from other ladder designs. This comprehensive overview delves into the purpose, applications, safety considerations, design, inspection, maintenance, regulations, and industry uses of these ladders, providing a thorough understanding of their role in various work environments.

These ladders, often employed in industrial settings, are designed to provide access to elevated areas or equipment without the need for additional fall protection systems. Their unique features and considerations make them a valuable tool in specific applications, while also requiring proper safety measures and adherence to regulations.

1. Fixed Ladders Without Cages or Wells

Overview

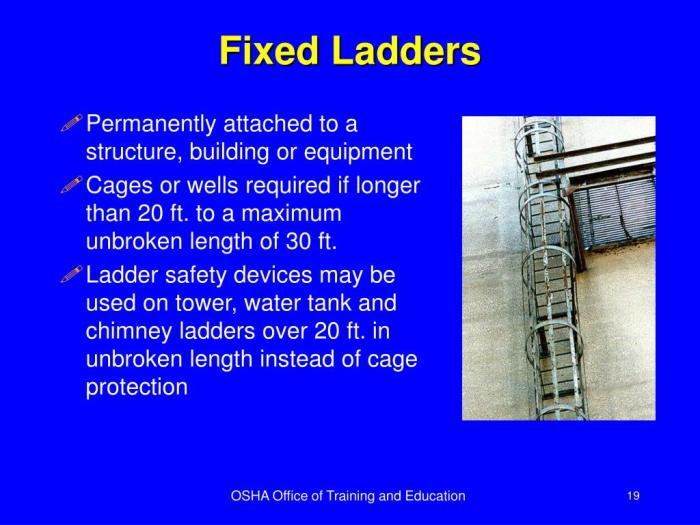

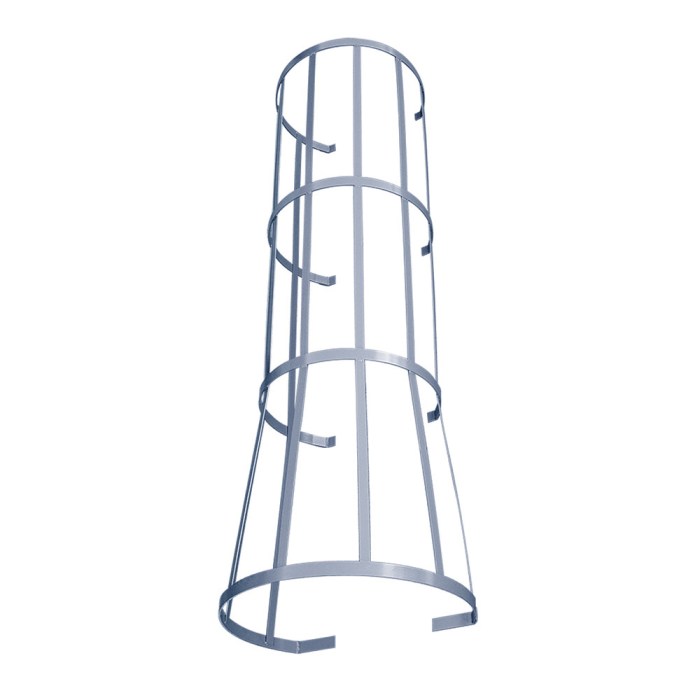

Fixed ladders without cages or wells are vertical ladders permanently attached to structures or equipment, providing access to elevated areas without the need for portable ladders. They are commonly used in industrial settings, construction sites, and other work environments where access to heights is required.

Compared to other types of ladders, fixed ladders without cages or wells offer advantages such as:

- Permanent installation:They are permanently attached to the structure, eliminating the need for setup or removal.

- Increased stability:Their fixed nature provides greater stability, reducing the risk of wobbling or tipping.

- Cost-effectiveness:They are generally more cost-effective than other types of ladders, especially for long-term use.

However, they also have some disadvantages:

- Limited portability:They cannot be easily moved or repositioned, unlike portable ladders.

- Potential fall hazards:Without cages or wells, there is an increased risk of falls, especially when climbing or descending at height.

2. Safety Considerations, Fixed ladders without cages or wells

Using fixed ladders without cages or wells requires careful attention to safety. Potential hazards include:

- Falls:The absence of cages or wells increases the risk of falls, especially when climbing or descending at height.

- Slips and trips:Wet, icy, or oily surfaces can increase the risk of slips and trips while using the ladder.

- Electrocution:If the ladder is in close proximity to electrical wires or equipment, there is a risk of electrocution.

To ensure safe use, it is crucial to adhere to safety regulations and standards, such as:

- OSHA regulations:Occupational Safety and Health Administration (OSHA) regulations govern the use of fixed ladders in the workplace.

- ANSI standards:American National Standards Institute (ANSI) standards provide guidelines for the design, construction, and use of fixed ladders.

Additional guidelines for safe use include:

- Proper climbing techniques:Maintain three points of contact with the ladder (two hands and one foot, or two feet and one hand) at all times.

- Fall protection measures:Use fall protection equipment such as safety harnesses and lanyards when working at height.

- Regular inspections and maintenance:Regularly inspect and maintain the ladder to ensure it is in good working condition.

FAQ Section: Fixed Ladders Without Cages Or Wells

What are the primary advantages of using fixed ladders without cages or wells?

Fixed ladders without cages or wells offer advantages such as reduced cost compared to ladders with cages, easier installation and maintenance, and a smaller footprint, making them suitable for confined spaces.

What are the key safety considerations when using fixed ladders without cages or wells?

Safety considerations include potential fall hazards, the need for proper climbing techniques, regular inspections, and adherence to safety regulations and standards.

What are the common applications for fixed ladders without cages or wells?

These ladders are commonly used in industrial settings, such as manufacturing plants, warehouses, and construction sites, to provide access to elevated platforms, equipment, and structures.